Sampling

Usually, sampling is performed by applying very small amounts of target substances which can´t be measured by using a scale. The samples need to be prepared by making a solution of the target substance and a solvent. This solution is being pipetted on a substrate, where the solvent evaporates. Unfortunately, with the test for Delta R the material in which the target substance is placed, consists of materials often used in shoes, for example, leather, canvas or spandex. When placing the solution directly on these substrates, the fabric immediately absorbs the fluid, leaving only a small part on the surface.

The Bottleneck

As the Delta R technology is based on detection on the surface, it is not possible to create samples this way. In order to still get these small amounts of target substance on the surface of the substrate, the solution is currently placed on an intermediary non-absorbing material to let it dry, after which it is transferred to the actual substrate. This is called ‘dry sampling’. Because the use of this method of dry transfer inevitably leads to small amounts of the target substance being left behind on the intermediate transfer medium, the currently used method is not optimal.

New Sampling Method

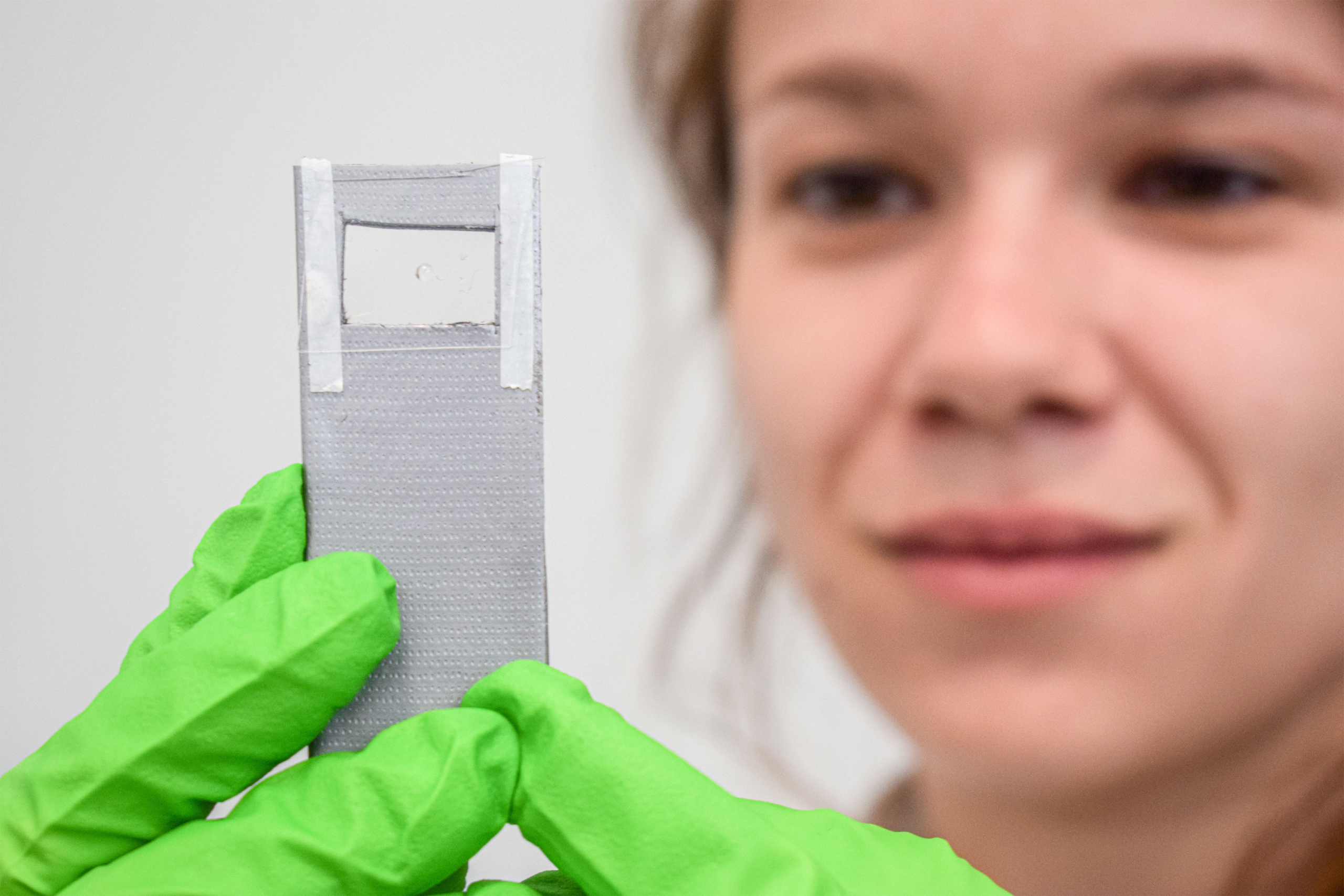

In order to find a method that’s more suitable, she compared three sampling methods: the currently used method, “Stamping”, an alternative method based on the use of Bytac, and a method that Dionne developed, based on the strengths of various methods sourced from literature. In her research she compared and weighed these transfer methods based on reliability, ease of use, costs, and more factors.

Dionne’s method is based on the use of FEP plastic, an inert, flexible, strong and see-through material. Combining this with the Bytac method’s intermediary transfer medium, adding an extended flap for ease of handling, has been shown to be advantageous and successful at Stage Gate 11. Dionne created a device that can be used and reused to transfer the target substance from the FEP to the substrate once it is dried.

Something we are proud of! We are very pleased to announce she will join our team as Test Engineer.

As she states: ‘During this research I gained exposure and significant amount of knowledge into the aviation domain, from experts, institutions and industries which helped me curate my work. I am grateful for this opportunity and would like to thank all the support I received at Stage Gate 11. ‘

Interested in doing an internship at SG11? Contact Rob Satink

+31 (0) 88 250 16 00 / insight@sg11.nl